-

-

Mon - Sat 9:00 AM - 6:30 PM

-

Plot No. 366, Shree BS Chemicals, Sector 29, Part 2, Panipat, Haryana

Emulsifier 9.5 (Textile Chemicals)

Emulsifier 9.5

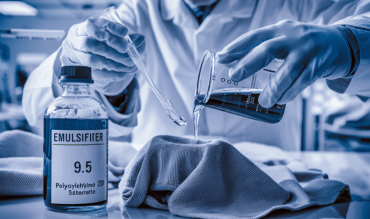

Emulsifier 9.5 is a non-ionic surfactant widely used in textile processing for its excellent wetting, emulsifying, and dispersing properties. It belongs to the ethoxylated nonylphenol group, specifically with approximately 9.5 moles of ethylene oxide. This surfactant plays a crucial role in textile pre-treatment, dyeing, scouring, and finishing processes by improving the solubility and stability of chemicals in aqueous solutions.

Emulsifier 9.5 is a high-performance non-ionic surfactant essential in textile processing, providing superior emulsification, dye dispersion, and fabric wetting for improved quality and efficiency.

Emulsifier 9.5 helps in removing oils, grease, and waxes from fabrics, ensuring better dye penetration and color uniformity. It also enhances the dispersibility of dyes and chemicals, leading to improved fabric quality. Due to its high stability and compatibility with other textile chemicals, it is widely used in textile formulations to achieve superior processing results.

Uses of Emulsifier 9.5 :

-

Anti-Re-Deposition Agent

-

Foam Control in Processing

-

Leveling Agent in Dyeing

-

Stabilizer in Printing Pastes

Can Emulsifier 9.5 help prevent dye streaks on fabric?

Yes, it acts as a leveling agent, ensuring uniform dye penetration and reducing streaks or uneven coloration.

Can Emulsifier 9.5 be used in high-speed textile machines?

Yes, it functions as a lubricant, reducing friction between fabric and machine parts, preventing wear and tear.

Does Emulsifier 9.5 work in low-temperature processing?

Yes, it remains effective at lower temperatures, making it suitable for energy-efficient textile processing.