-

-

Mon - Sat 9:00 AM - 6:30 PM

-

Plot No. 366, Shree BS Chemicals, Sector 29, Part 2, Panipat, Haryana

Wicking & Anti-Static (Textile Chemical)

Wicking & Anti-Static

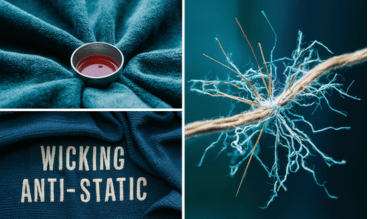

Wicking is the process of managing and transferring liquid moisture in or on a garment or textile. Wicking, wetting, and drying rate are test methods that determine the efficiency of moisture management.

Anti-Static finishes are used to remove the negative effects of electrostatic charge from synthetic fibers during production and wear.

Antistatic finishes are used to remove the negative impacts of electrostatic charge created during the production and wear of fabrics and knits. The impact of anti-static chemical treatment can be temporary or permanent.

Benefits Of Wicking & Anti-Static :

-

Improve comfort and durability

-

Protect against electrical discharge

-

Sterilize effectively

-

Have high density and strength

-

Help prevent damage to equipment

What are Wicking & Anti-Static In Textile Industry?

Anti-static agents for textiles that prevent statics when wearing clothes, and also prevent dust from attaching to the fabrics during the sewing process and thread from tangling on the machine during finishing process.

Effects Of Wicking & Anti-Static In Textile Industry?

Anti-static finishes can remove unwanted effects of electrostatic charge that occur during production and wear of synthetic fibers. Anti-static clothing can also protect against electrical discharge, improve comfort and durability, and help with compliance with industry regulations.